An informational site dedicated to process control education. Posts on this blog contain interesting and noteworthy information about process instrumentation, valves, and equipment used in industrial and municipal facilities. This blog is sponsored by Instrument Specialties, Inc. (ISI). For more information, please visit ISI.GROUP

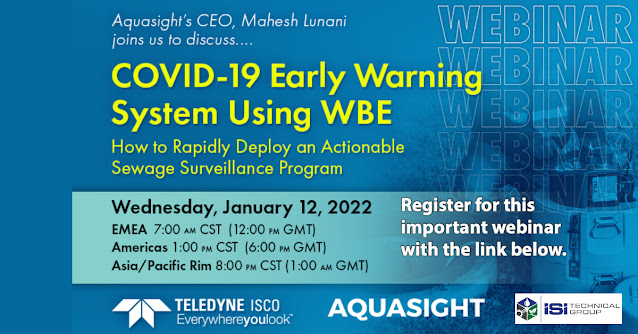

Important Covid-19 Early Warning Wastewater-based Epidemiology Webinar January 12, 2022

Covid-19 Early Warning Wastewater-based Epidemiology Webinar Topics

- Wastewater sampling site selection

- Sampling instruments - selection and installation

- Sample optimization and SCADA control

- Sample preservation and transport

- Lab testing and minimum detection levels

- Key Performance Indicators (KPIs)

- Predictive analytics and advanced decision support tools including rapid identification of hot spots and high-risk areas

AUMA Electric Actuators for Critical Flow Control, Safety, and Security in the Water Industry

Automatic Samplers Assist in Detection of Pathogens, Viruses & CECs via Wastewater-based Epidemiology

WBE (or wastewater-based epidemiology or sewage chemical information mining) is a technique for identifying a population's consumption or exposure to chemicals or diseases. A sewage treatment facility measures chemical or biological entities (biomarkers) in municipal wastewater to do so. In addition to illicit drug usage, wastewater-based epidemiology can quantify alcohol, caffeine, medicines, and other chemicals. Wastewater-based epidemiology can also detect diseases like SARS-CoV-2 in a population. Wastewater-based epidemiology is a multidisciplinary effort including wastewater treatment plant operators, chemists, and epidemiologists.

Professionals in water quality use the term contaminants of emerging concern (CECs) to describe pollutants found in water bodies that may harm the environment or human health but are not currently regulated. Agriculture, urban runoff, ordinary household products (like soaps and disinfectants) and pharmaceuticals are all sources of these pollutants.

Natural and synthetic hormones are emerging contaminants, as is 1,4-dioxane. CECs can enter the water cycle after being discharged as waste via runoff into rivers, effluent discharge, or seepage and infiltration into the water table, eventually entering the public water supply system. Some emerging contaminants are known carcinogens and cause endocrine disruption and other toxic mechanisms.

The full line of Teledyne ISCO samplers can assist local governments, private industry, colleges and universities, and many others in detecting the COVID-19 virus, pharmaceuticals and CECs in wastewater and providing the information needed to create a plan of action.

For more information about Teledyne ISCO product in Florida, contact Instrument Specialities, Inc. Call 407-324-7800 or visit https://isisales.com.

The Ideal Air Release Valve for Chemical, Desalinization, Sewage, and Other Severe Applications

The Crispin X Series elevates valve maintenance into the twenty-first century. All of the valve parts are made of stainless steel, making them rustproof. Instead of a bolted, flanged connection, the X series uses a stainless circular clamp to secure the valve head to the body for the tightest seal in the industry.

The X Series, available in Air & Vacuum, Pressure Air Release, and Combination assemblies, features Crispin's exclusive Head Exchange System, which includes head-fixed stainless steel valve internals. Simply loosen the head assembly, held in place by a sanitary stainless clamp fitting, to clean. Remove the original head, which weighs less than 10 pounds, and replace it with a spare. Then, at your leisure, clean the original internals. Backflushing inline is no longer possible. No more annoyances. ANSI/AWWA C512 compliant.

The internals of all valves are attached to the head, which is available in three color-coded configurations: red for the Air & Vacuum valve, green for the Pressure Air Release valve, and blue for the Universal Combination valve. Each product's packaging is also color-coded for easy storage.

When backflushing an inline X Series valve, the spare head replaces the original valve head immediately, allowing proper cleaning to take place off-site in a safer and more sanitary environment.

All that stands between you and a clean valve with the X Series is a wrench, two bolts, and a clamp.

All of the valve heads fit the same virtually indestructible 316 stainless steel body. It is one-third the weight of a standard cast iron body and has a polished interior that prevents buildup because debris has nothing to cling to. Crispin valves are all tested under the most recent ANSI/AWWA C512 standards.

For more information about Crispin Valves for the municipal water industry in Florida, contact Instrument Specialties. Call them at (407) 324-7800 or visit their website at https://isisales.com.

Smart Wastewater Pump Stations with MAID Labs Volucalc™

A wastewater lift station is a pumping station that transports wastewater from one elevation to another. They are essential in transporting sewage to a wastewater treatment plant. Lift Stations are an integral part of the overall infrastructure of the wastewater industry. They improve the efficiency with which sewage transports to treatment facilities. They also reduce the cost of installing underground sewer pipes. It is critical for wastewater treatment operators to closely monitor the health and efficiency of their equipment, paying close attention to alarms and notifications. Monitoring not only extends the life of the equipment but also ensures public safety (sewage is a hazardous material that must be handled and transported with caution.)

Multiple operational parts and components make up a functional wastewater lift pump station. Everything from a power supply to remote monitoring and control must be functioning to collect and treat wastewater properly.

A Flow-Based Lift Station Operating System changes the operation of the pumps based on the flow rate entering the lift station in real-time, increasing the pumps' capacity by reducing the head. It raises its ability to cope with storm surges by lowering the lead level during high flow conditions. Real-Time flow rate monitoring is mandatory to respond to rapidly changing conditions.

Consistent monitoring is required to operate and maintain a wastewater lift station properly. A cloud-based monitoring system is the most effective approach to monitoring and controlling a lift station because they are simple, inexpensive, accurate, and accessible from anywhere. Such monitoring systems give wastewater operators access to data about their lift stations, including alert notifications and historical data graphs and charts. Monitoring ensures that lift station equipment is in good working order and protects the public by giving vital information about the wastewater being transported and processed.

MAID (Municipal And Industrial Data) Labs created the only wastewater pump station computer that significantly reduces the electrical consumption using the existing equipment. Power consumption, pump efficiency, level behavior, and real-time high precision volumetric flow metering are some elements used to highlight the embryonic catastrophic situation. The MaidLabs' Volucalc™ Hybrid Series provides a better way to manage wastewater pump stations and is the future of lift station analysis.

Volucalc™ Hybrid CS (Constant Speed)

VOLUCALC™ HYBRID CS is a volumetric flow meter and an open channel flow meter applicable to lift stations with constant speed pumps reporting abnormal behaviors using real-time diagnostics with flow and efficiency monitoring. The CS potentially decreases electric bills by 15% to 30% using the flow-based operating system.

Volucalc™ Hybrid VS (Variable Speed)

VOLUCALC™ Hybrid VS is a volumetric flow meter, a derived flow-based flow meter, an open channel flow meter, a backup pump controller, and an efficiency optimizer applied on lift stations having constant speed and variable speed pumps. On constant speed pumps, flow is calculated with a volumetric algorithm. On variable speed pumps, the flow rate is derived from the calibrated pump curves. A rain gauge can also be connected for infiltration studies.

For more information in Florida, contact Instrument Specialties. Call (407)-324-7800 or visit https://isisales.com.

Video Demonstrates Teledyne ISCO Automatic Sampler's Real-World Role in Detecting COVID-19 in Wastewater Systems

Researchers at UC Berkeley are using a simple and effective method for detecting the presence of the Coronavirus in wastewater flowing through municipal sewer systems. Water testing will assist public policymakers to determine where and how to implement COVID-19 prevention and treatment plans.

Wastewater testing, also known as "wastewater quality indicators," is a broad term for the various test methodologies used to measure water quality. These tests investigate the physical, chemical, and biological properties of wastewater. Wastewater naturally collects waste from hundreds to even millions of people in a single sample. By drawing a representative sample of wastewater and analyzing it, you can gain a tremendous amount of information that you would likely not be able to achieve by testing people individually.

The amount of viral matter in wastewater from a community could reveal the prevalence of COVID-19 in the population. This information can trigger the necessary mitigation initiatives and response plans, such as individual testing, contract tracking, and quarantine. It also allows for collecting data on a cross-section of the population, allowing for the monitoring of public health solutions for large groups. However, it is challenging to detect tiny virus particles in the wastewater that flows through our sewage pipes, considering it includes toilet water and sink water, shower water, and everything else that goes down the drain. Teledyne ISCO is leading the way in the use of automatic samplers for gathering wastewater to identify virus evidence in sewage.

Teledyne ISCO is a leading manufacturer and supplier of rugged, dependable field-portable instruments for water quality monitoring. Their automatic sampler readings analyze the characteristics and presence of the Coronavirus in parts per million quantities, which, when compared to population numbers in a geographic area, aids in determining the presence and amount of virus in the wastewater.

The above-referenced UC Berkeley videos provide a real-life example of how the Teledyne ISCO water sampler collects wastewater for COVID-19 analysis. In this video, samples are gathered from their University Village and sewers draining from UC Berkeley's undergraduate dormitories and surrounding neighborhoods.

The full video link is here. https://www.youtube.com/watch?v=FwsRUw4y_dU.

The full article outlining UC Berkeley's initiative is here.

For more information about Teledyne ISCO samplers used for Covid detection in Florida, contact Instrument Specialties, Inc. Call 407-324-7800 or visit https://isisales.com.

The Eye-Hye SmartLevel Boiler Indication System from Clark Reliance

All New SC Series Control Unit

- Status Indicator for Each Level Sensing Module

- Operator can quickly be alerted to loss of power, processor interruption, water indication and blowdown mode.

- Lamp Test Feature

- Comes standard without cost of additional circuits or field wiring.

- Voting Logic Circuitry

- System is field-selectableto set the level of alarm or trip output. Standard feature.

- System Fault or Blowdown Indication of External Switch

- Can direct alerts to any external system or device, not just control room indicator.

- Accepts up to two Separate Power Sources from Separate Breakers

- Assures continuous system operation.

- System Operates on 85 to 264 VAC 50/60 Hz

- One model for worldwide use. Simplifies specification requirements for EPCs, OEMs and contractors.

- Multiple Remote Indicators Can be Installed up to 1 Mile (1.61 Kilometers) Away

- You can have duplicate indicators wherever you choose for operator convenience.

- Level Detection Sensitivity

- Field selectable:

- Sensitivity for extreme water conditions

- Time delay on actuation and release

AUMA Electric Actuators for the Water Industry

Clean water is the basis of all life. Potable water production and distribution, sewage treatment, and disposal are core tasks of modern water management.

AUMA electric actuators ensure dependable valve automation in these areas of water, wastewater treatment, and municipal water facilities:

- Sewage Treatment Plants

- Water Treatment Plants

- Drinking Water Distribution

- Sewage Disposal

- Sea Water Desalination

- Irrigation Systems

- Civil Engineering Constructions for Water Applications (Sluice Gates, Weirs, Dams)

AUMA actuators earned an excellent reputation by meeting the particular challenges and finding the perfect solutions in the water industry. Today, the AUMA brand is a synonym for long service life and ruggedness. For several decades, AUMA actuators have provided reliable and efficient service worldwide while requiring very minimal maintenance.

From individual actuators for municipal sewage treatment plants to major projects combining several hundreds of units, from the small butterfly valves, to ball valves, to weirs several meters high, AUMA solutions meet all customer demands.

AUMA modular products are easy to retrofit in an existing installation when upgrading with modern actuation and control technology.

Whether integration in established PLC control concepts or the latest Fieldbus technology, AUMA actuators guarantee adaptability into any control system design.

For more information about AUMA electric actuators for the water industry in Florida, contact Instrument Specialties. Call them at (407) 324-7800 or visit their website at https://isisales.com.

Teledyne ISCO Water & Wastewater Webinar Library

Teledyne ISCO's Water & Wastewater Webinar Library provides a wealth of information for water and water treatment professionals and are a great way to learn about water sampling technology and flow management. Teledyne ISCO webinars offer timely information from experts and provide the flexibility to view at your convenience without the travel expense.

Explore their recurring and on-demand webinars on various product implementation strategies and recommended practices for water sample analysis and data collection. Teledyne ISCO regularly adds new content, so check back frequently for new webinars.

VISIT TELEDYNE ISCO'S WEBINAR LIBRARY

WATER & WASTEWATER WEBINAR TOPICS

- PFAS Sampling Strategies

- What to Consider When Collecting Water Samples

- Cipher: Data Collection Anywhere, Anytime on Any Device

- Ask ISCO: All About Portable Sampling

- Fundamentals of Open Channel Flow Rate Measurement

- Tips and Tricks for Winter Sampling Webinar

- Measuring Flow Rates in Large Channels and Rivers

- Measuring Flow in Difficult Conditions

- Confirming the Accuracy of Open Channel Flow Data

- Advanced Technologies for Monitoring COVID-19 in Wastewater

- Confirming the Accuracy of Open Channel Flow Data

- Laser & Radar Sensors for Open Channel Measurement Applications

- Tracking COVID-19 in Wastewater

- Open Channel Sensor Diagnostics

- Increasing Safety & Minimizing Exposure with Collection System Flow Measurement

- Firmware Updates to Improve Your Performance

- Preparing for the Wet Weather Monitoring Season

- Troubleshooting and Optimizing ISCO Communication Devices

- Open-Channel Flow Measurement 101

- Collecting Samples: Placement, Setup, and Programming

- Measuring Flow in Hazardous Applications

- Ask ISCO: Measuring Open Channel Flows

- Ask ISCO: About Vacuum Sampler

- Hazardous Areas and the LaserFlow Ex

- Measuring Flow in Difficult Conditions

- Ask ISCO: Collection System Flow Monitoring

- Vacuum vs. Peristaltic Pump Samplers: Which is Right for You?

- Efficient Ways to Do Stormwater Sampling

- Things to Consider When Using Collection System Flow Meters

- ASK ISCO: Portable Sampling

Control Valve Cavitation Solutions

Cavitation is the formation of vapor spaces (bubbles) in the control valve cavity resulting from a rapid change in pressure. When the bubbles move downstream and are exposed to a larger cross-sectional area, velocity decreases and pressure increases, the surrounding higher pressure causes the lower pressure bubble to implode, which causes shockwaves. These shockwaves can cause metal fatigue and cause excessive wear on the internals of the valve. As the bubbles collapse, they make a discernible sound with accompanying vibration, and the damage to a valve can happen quickly (weeks or months).

Cavitation is very destructive and may wear out the trim and body parts of the valve in a short time. Using hard internal materials provides a slight improvement but costs more.

Flowserve Valtek Cavitation Solution Control Valves prevent cavitation damage and minimize hydrodynamic noise even under the most severe liquid applications. Their unique, patented designs eliminate cavitation damage and provide straightforward maintenance and a long life even with demanding applications.

For more information about Flowserve Valtek Control Valves in Florida, contact Instrument Specialties by calling +1 407.324.7800 or visiting https://isisales.com.

Actuator Advancements in the Water & Wastewater Industry

AUMA actuation solutions are used for open/close valve applications to divert flow to respond to the water treatment plant requirements and perform flow control duties to operate the valve. In modulating applications, the actuator precisely controls the flow to adjust the amount of medium passing through the valve into or out of the treatment plant.

AUMA has a long history as a leader in electric actuators for the water management and water treatment sectors. They maintain their leadership position through innovation and technological advancements. Here are a few examples:

Leading the Effort for Automation of Electric Actuators in Water & Water Treatment

- AUMA Cloud - Cost-Effective Asset Management and Condition-Based Predictive Maintenance

- AUMA Assistant App - Quick & Easy Setting, Comprehensive Diagnostics, Data Cloud Storage, Fast Support, Documents at Your Fingertips

- Electric Actuators for Continuous Underwater Use

Pressure Switches Are Unsung Heroes in Many Process Control Applications

In today's highly connected world of process control instrumentation, the unacknowledged and uncelebrated pressure switch quietly does it's job protecting people and equipment from unsafe conditions and ensuring consistent, efficient operation.

A pressure switch is an electromechanical device that senses fluid pressure and responds by opening or closing an electrical or pneumatic circuit. That's it. That's their job.

However, pressure switch applications exist in almost every water treatment plant, power plant, refinery, chemical plant, paper mill, steel mill, or other manufacturing plant. Pressure switches are everywhere.

Pressure switches are easy to use and consist of four essential components: a pressure port or connection; a sensor that moves in response to changing pressures; an electrical or pneumatic switch that opens or closes in response to movement; and finally, a housing that protects the pressure switch's internals from the environment.

SOR pressure switches, the recipient of a 2021 CONTROL Readers Choice Award, have been field-proven in many industries for primary and redundant pressure applications. SOR continues to broaden its product ranges to meet evolving market needs, even though the technology of the initial Static "O" Ring mechanical switches set industry standards more than 50 years ago. In any situation, there's a SOR switch designed to meet or exceed the minimum requirements for any hazardous area or agency approval.

SOR pressure switches are designed and offered with various agency permits, housing enclosures, sensor materials, and switching configurations. The wide range of product components allows for the best instrument configurations to handle even the most demanding applications.

For more information about SOR pressure switches in Florida, contact Instrument Specialties. Call them at 407-324-7800 or visit this web page.

Your Local Teledyne ISCO Representative is Ready to Assist with Applying Portable Samplers

Portable samplers enable water quality monitoring in a variety of remote locations. However, determining the right equipment and optimum configuration for the site can be a challenge. An asset you can reliably turn to is your local Teledyne ISCO Representative. They are your local source for new products, proper application, product obsolescence, and replacement. Also, because these experts have access to so many different types of applications and situations, your local Teledyne ISCO Representative is a wealth of tacit knowledge that they readily share with their customers.

For example, more and more municipalities are testing their wastewater for the SARS-CoV-2 virus. Wastewater-based epidemiology (WBE) uses Teledyne ISCO portable samplers to track COVID-19 in wastewater collection systems, proving helpful in controlling the pandemic. The use of sewage pathogen monitoring in wastewater treatment facilities as a public health surveillance tool is now a reality. Municipalities have at their disposal portable and refrigerated samplers ready for widespread collection and testing. Your ISCO Representative is prepared to outline the best ways to use this equipment as part of your overall Coronavirus strategy in any type of environment or testing situation.

Teledyne ISCO Representatives can assist you in applying portable samplers in these challenging situations:

- Sites with low flow

- Deep vertical sampling

- Fast flow, solids, ragging, and other challenging conditions

- Special considerations for wastewater-based epidemiology (WBE)

- Tracking COVID-19 in wastewater to help control the epidemic

- Sample preservation, cooling, and battery life

- Selecting the proper sampler for the location

It makes sense to develop a close relationship with these factory-trained, technical sales experts for water treatment professionals. They will help you gain better insight into the most commonly encountered problems in portable sampling applications and how to handle them.

In Florida, contact Instrument Specialties, Inc. Their phone number is 407-324-7800. You can also learn more at https://isisales.com.

Electric Actuators for the Water and Wastewater Industry

Drinking water abstraction and distribution and sewage disposal and purification are essential prerequisites for infrastructure development and security. As witnessed by recent events, the security of supply is crucial for the modern water industry.

AUMA is ubiquitous in the water industry due to its broad product portfolio, including multi-turn, part-turn, linear actuators, reliability, state-of-the-art communications, and security. In combination with high corrosion protection, they guarantee a long service life and low maintenance.

Because of this, you'll find AUMA electric actuators around the world in:

- Sewage treatment plants

- Water treatment plants

- Drinking water distribution

- Sewage disposal

- Seawater desalination

For more information about AUMA in the water, wastewater, and water treatment industry in Florida, contact Instrument Specialties. Call them at +1 407-324-7800 or visit their website at https://isisales.com.

Siemens Medium Voltage Drives: Digitalization

Recommended Blowdown Procedure for Boiler Level Instruments

Proper maintenance of boiler water level instruments is crucial to keeping your plant running safely and efficiently, at all times. This educational video demonstrates how to conduct a proper blowdown procedure on a glass boiler water gage and a remote level indicator. Courtesy of Clark-Reliance.

For more information contact Instrument Specialties. Call them at 407-324-7800 or visit their website at https://isisales.com.